Sustainability has always been a driving force for Submaterial.

Our mission states: Submaterial creates thoughtful and enduring design products by hand. We transform places and spaces by bringing function and beauty to the world through the conscientious use of materials and responsible manufacturing methods. We also have named very clear values, including a focus on our world. We are future-focused and mindful of the impact our work has on the world. Our environment and our community are deeply important to us. We continuously seek opportunities to improve.

We are not zero waste. We are not perfect in our sustainability efforts. We accept that, but as our value states, we continuously seek opportunities to improve. Here are some of the ways:

The Materials We Use

100% MERINO WOOL FELT:

One of the oldest man-made textiles, wool felt is an excellent material for our designs. It is flexible, durable, water-resistant, self-extinguishing, and takes color with deep saturation. Wool felt also has sound-dampening properties, which makes it superbly useful in interior environments.

NATURAL CORK:

We source our cork from Portugal, where the cork forests are ancient, dense, and responsibly harvested. It is also carbon neutral. Cork is lightweight, impermeable, fire-retardant, hypoallergenic, and odor-free.

OTHER MATERIALS:

We use responsibly felled and processed domestic solid woods and veneers whenever possible.

We use full-grain vegetable-tanned leathers produced with a low-waste factor.

ADHESIVE:

The adhesive we source is water-based, no-VOC, formaldehyde-free, and ROHS-compliant.

Lean Manufacturing

8 WASTES OF LEAN MANUFACTURING

We use natural materials by preference because they work for us and the planet. Within that sustainability mindset, we are also thoughtful once the items are in our studio and ready to be manufactured into our products. Over the last half-decade, we have been working towards a lean manufacturing process. Lean is a production process based on an ideology of maximizing productivity while simultaneously minimizing waste (time, materials, and cost) within a manufacturing operation. All staff (fabrication, design, marketing, admin) have undergone lean training with the local New Mexico Manufacturing Extension Partnership (NM MEP).

An important part of lean is removing unnecessary transportation and excess inventory. Our inventory of materials is a careful record-keeping of what we have in-house. This keeps us from over-ordering, shipping, and storing more than we need and prompts us to look for ways to create with what we already have. For example, many of our prototypes, created to test out a particular material or manufacturing method, are done in unusual color combinations. But we would rather that than the cost, time, and additional carbon footprint of ordering more material.

Sustainability and Workers' Rights

Submaterial is shaped by the people who work here every day. With such a talented and hard-working team, we strive to foster a stable and healthy working environment.

Our employees are paid fairly. We start all employees at or above the local living wage because regardless of role, everyone is valuable, and we want their work to be compensated fairly.

We offer fully covered health insurance for all of our employees, with no waiting period. Fabrication is physically taxing and we want our team to be able to take care of themselves as best as they can.

Everyone is eligible for PTO. We value a good work-life balance and encourage our team to take time off when needed.

Our choices of materials, tools, and adhesives are made with the health and safety of our tea

Recycling

Cork is our second most used material. And given our specific manufacturing application, we end up with many small pieces of cork offcuts. Thankfully, ReCork exists. We pack and pay for shipping a large crate full of cork scraps to Napa, California. In their facility, post-consumer and post-industrial cork are re-agglomerated in a patented technique to create ReCORK Recycled Cork. The new material replaces petroleum-based foams and plastics in consumer products and can be collected and recycled again!

For about 18 months, we were thrilled to send our finishing scraps (cork and felt strips with minimal adhesive) to a local composting facility. We, unfortunately, had to pause that effort in the fall 2024.

In the spring of 2025, we began a relationship with TerraCycle. We are working with them to recycle not only our organic wool and cork production waste, but also our PET acoustic board waste, which is a new venture for us. We are excited to see how this material recycles and if we can work on something closer to circularly with it.

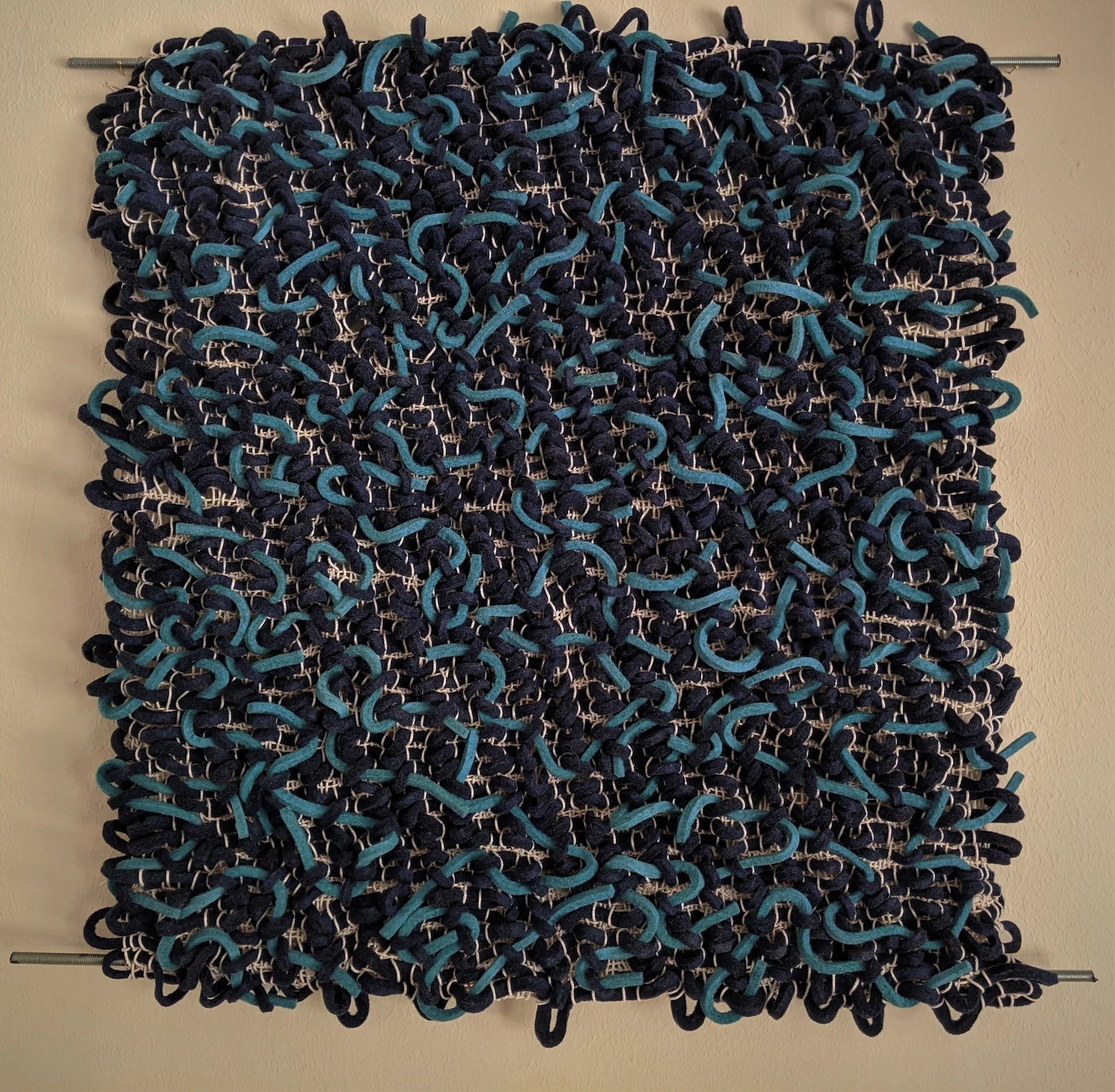

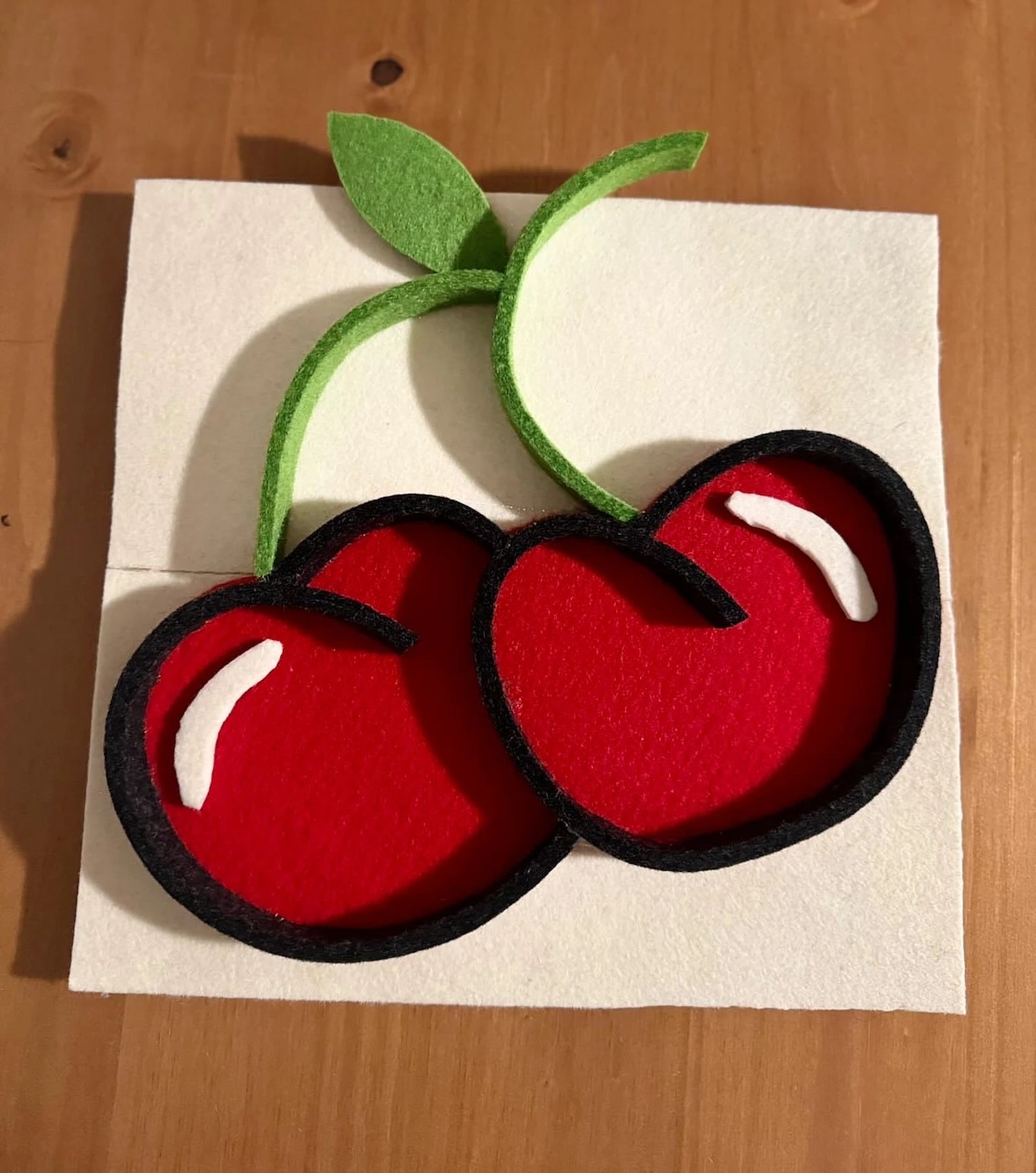

Creative Reuse

Felt scraps, often brightly colored and of various sizes, are given away or donated to artists, makers, schools, museums, and honestly, anyone who wants them. In the fall, we often use our undersized material to make dog toys for Animal Humane’s Doggie Dash and Dawdle event. But more than anything, we love to get the felt offcuts into the hands of folks who will do something fun and creative with them.

Here are some examples of how creative people have used our felt offcuts!